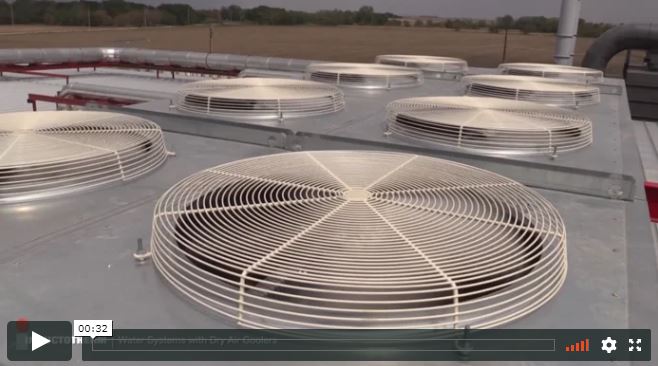

Dry Air Coolers

Water Systems with Dry Air Coolers (DAC) cut both operating and maintenance costs and are easy to install and maintain.

One major benefit to water systems with Dry Air Coolers is that they operate with zero water discharge. These simple, recirculating systems can provide excellent, year round cooling and are a closed-loop, air-cooled design. They typically consist primarily of a pump, hydronic tank, deionizer and an outdoor mounted water-to-air heat exchanger. They provide ideal cooling for many pieces of Inductotherm equipment and especially in climates where the dry bulb is at or below 100ᵒF (38ᵒC). A trim-cooler option is available for hotter climates that may occasionally exceed the limitations of a standard dry air cooler. Another great option offered by Inductotherm is our fan cycling package.

Another great option offered by Inductotherm is our fan cycling package. This upgrade allows only as many fans as is required to operate during given conditions to reduce your overall power consumption. By converting to a water-saving system, such as a dry air cooler, external water requirements can be reduced significantly. This will reduce melt shop operating costs and address environmental concerns associated with water usage.

Tech Specs

| Standard Features | Optional Features | Factory Tested |

|---|---|---|

| Zero Water Discharge | Trim Coolers for Additional Capacity | Critical Components |

| No Condensation Problems When Used with a Diversion Valve | Full-Access Water Pumping Modules | |

| Minimum Corrosion, Scaling and Electrolysis | Fan Cycling Controls for Reduced Power Usage | |

| Low Maintenance Costs | ||

| No Coolant Contamination | ||

| Completely Closed-Loop Pressurized Circuit | ||

| Air-Cooled Design | ||

| Reliable Year-Round Cooling | ||

| Emergency Cooling Capacity During Power Failures | ||

| Abnormal Temperature Protection | ||

| Audible and Visible Alarms |