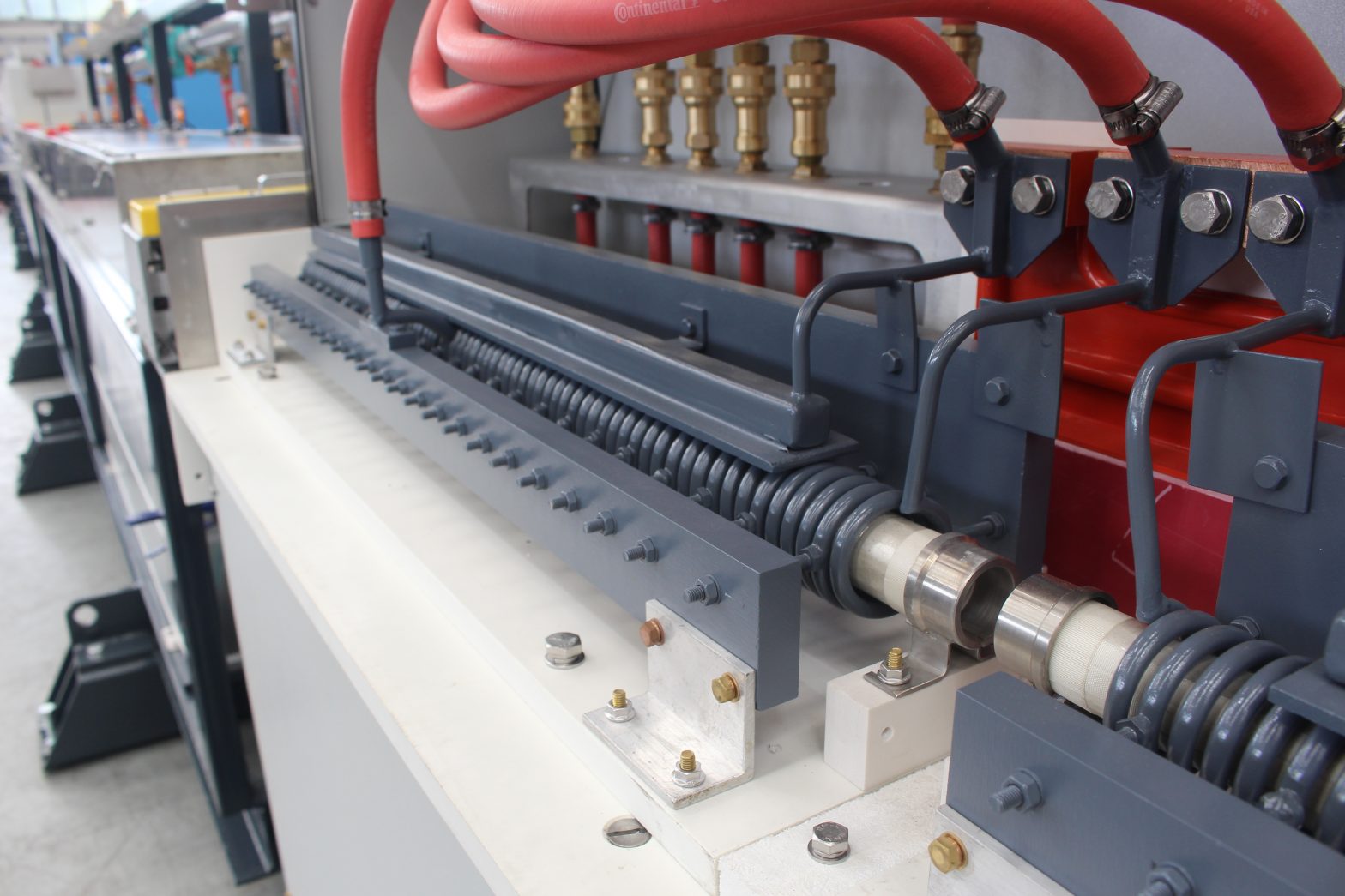

Spring Wire IT Line

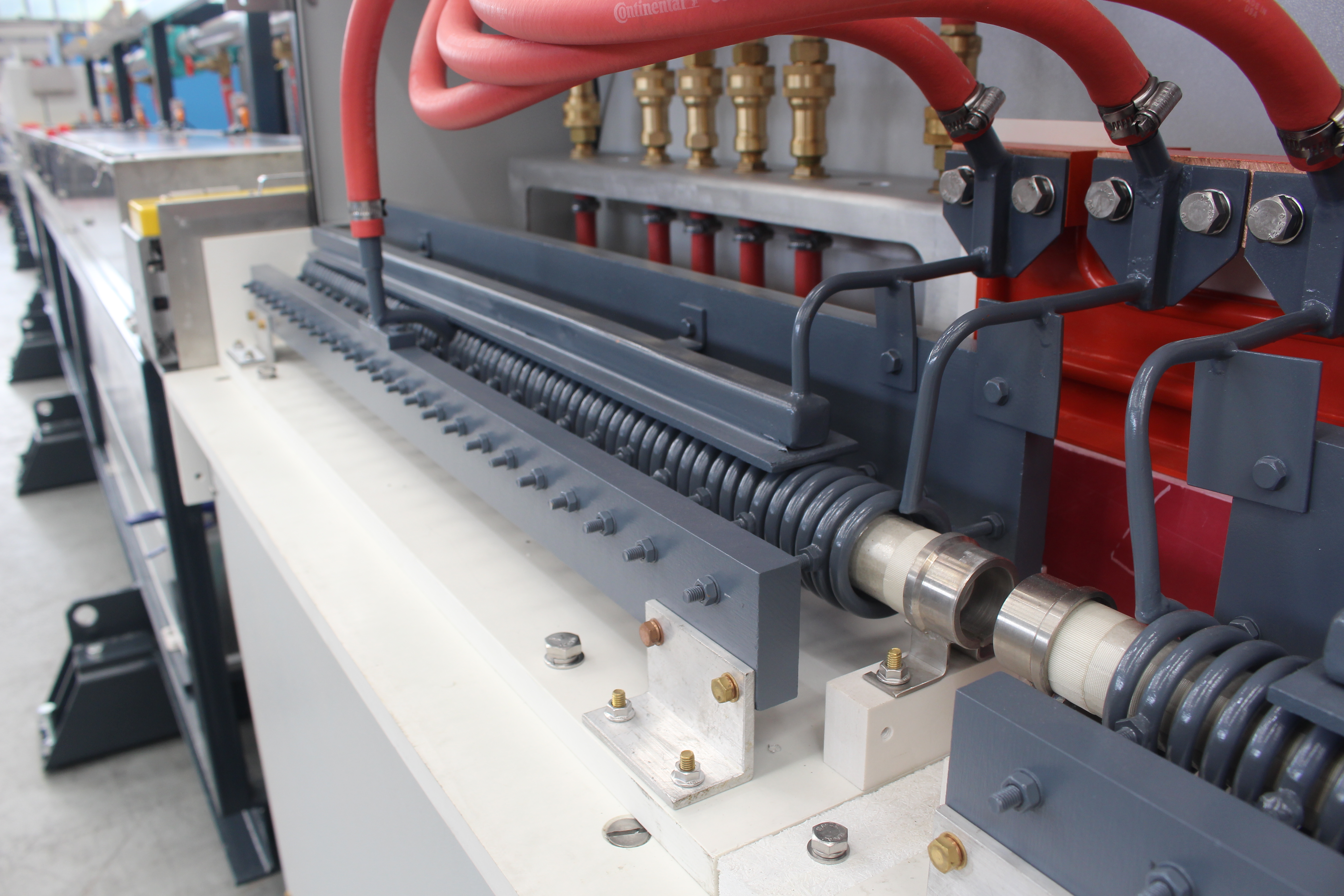

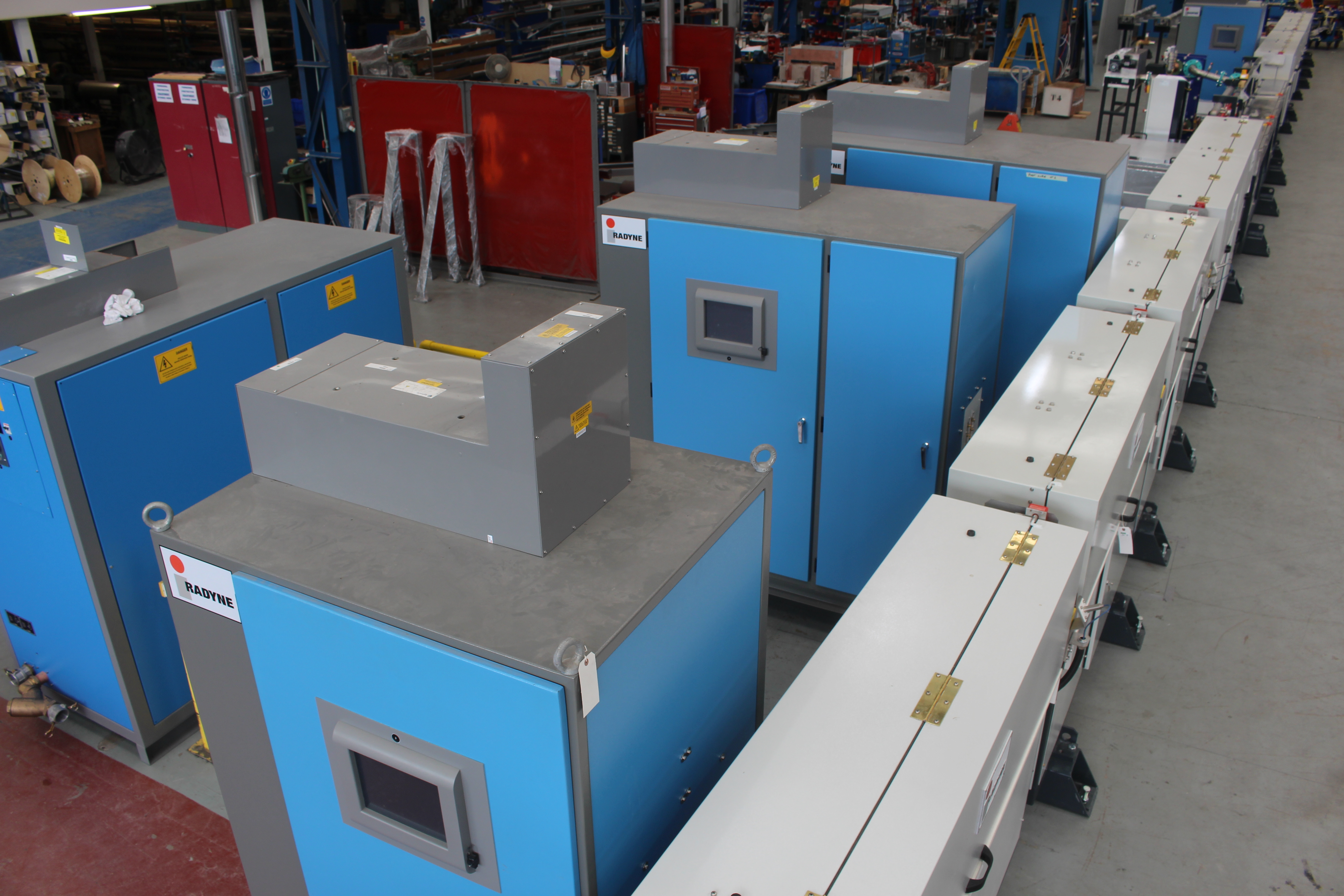

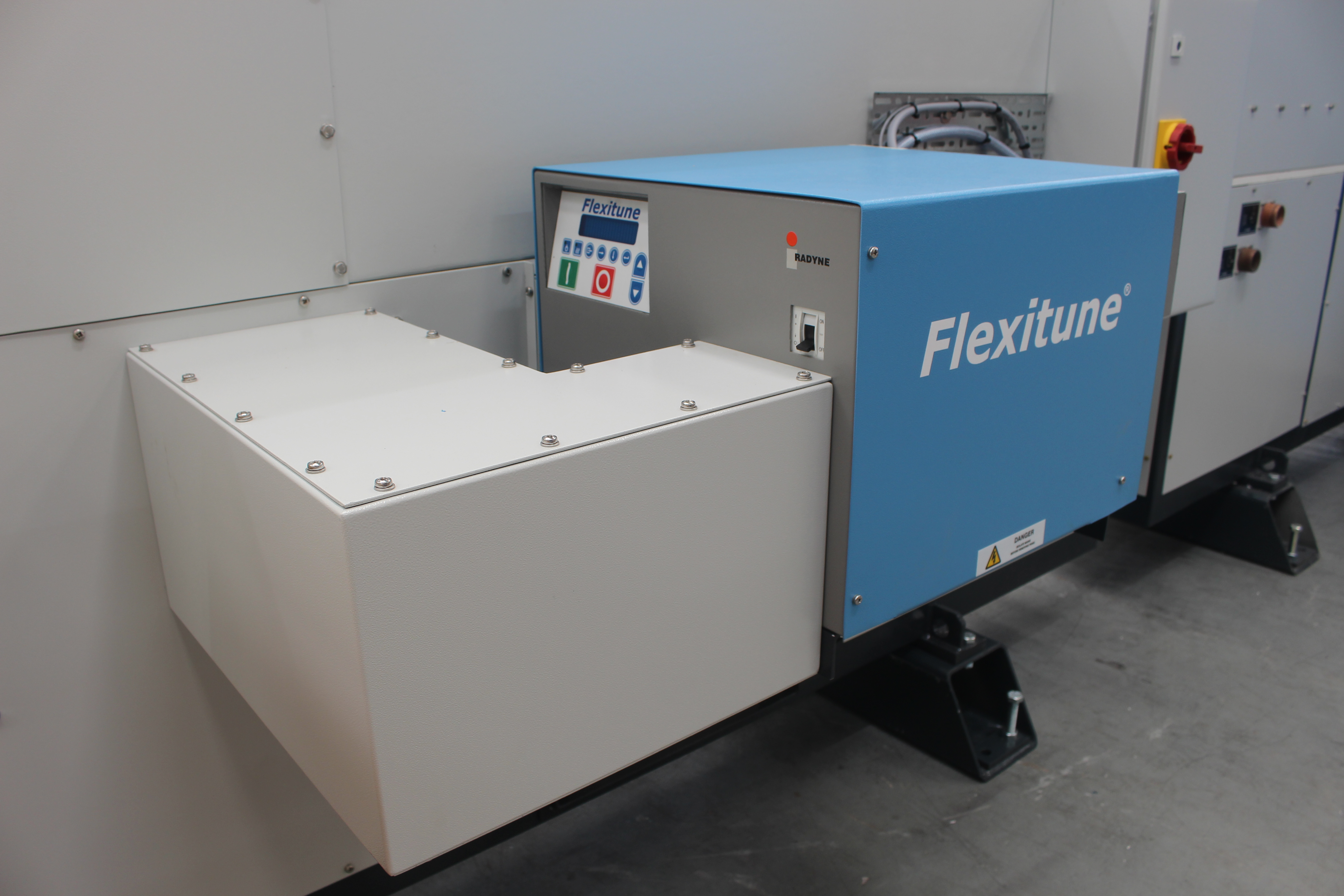

The Radyne Spring Wire IT Line is capable of high capacity production with a full turn-key solution designed to harden & temper spring wire using the highly efficient technology of induction heating.

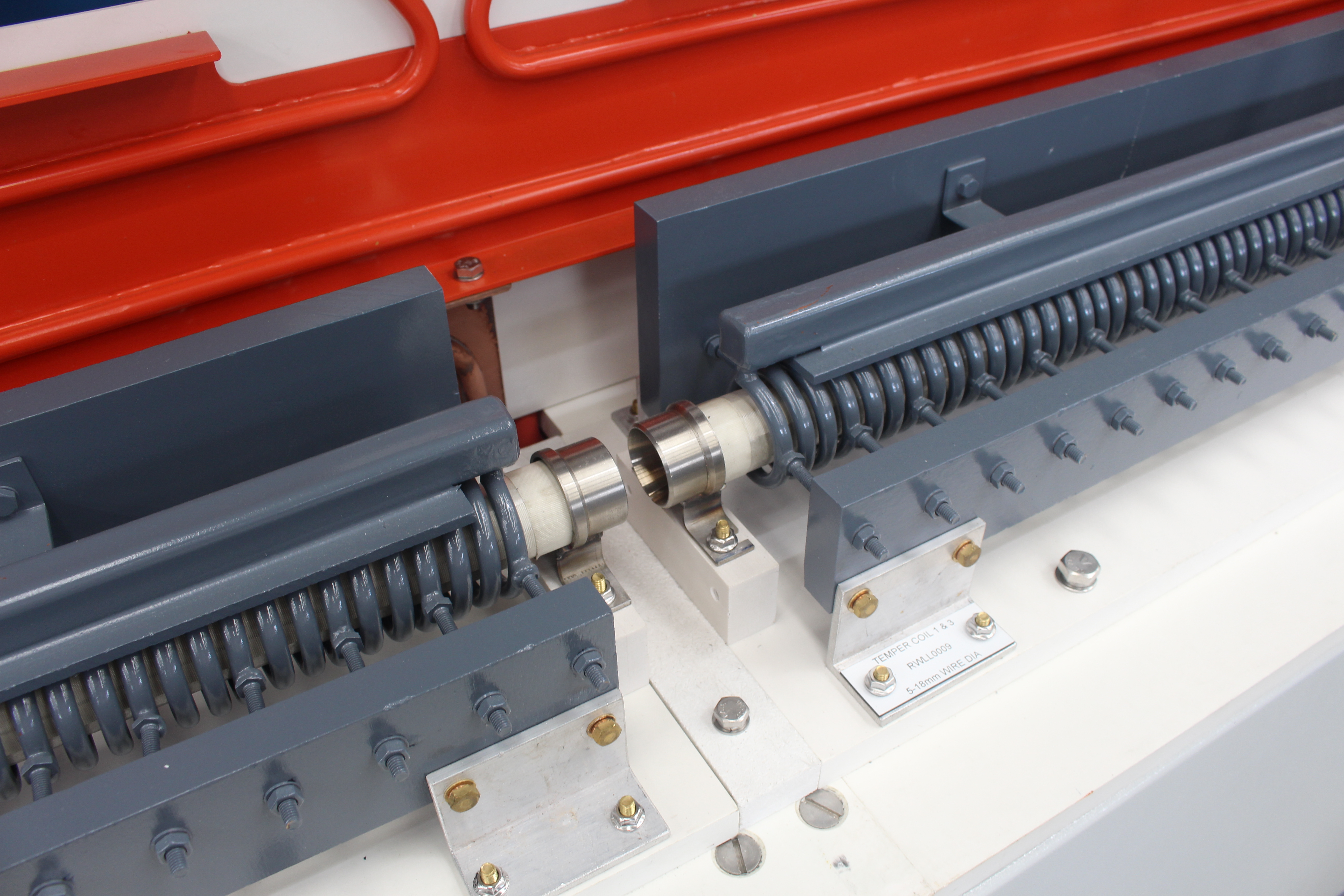

This long-established offering from Radyne is considered as the benchmark equipment for this process and is capable of handling wire diameters from 7mm to 17mm with production rates upwards of 3000kg/hour.

Optional equipment can include an in-line drawing block.

In the main, this line is used to process spring wire that will subsequently be “cold coiled” into products such as automotive suspension springs, motorcycle suspension springs, garage door springs, and general mechanical springs.

Features

- Uniquely, Radyne Spring Wire IT Line offer process guarantees that cover dimensional distortion, surface finish and defects, UTS and consistency amongst others.

- The most efficient, controllable and repeatable process of its type, its environmental credentials are also world-leading.

- Minimal fumes and almost zero exhaust gases, hot water washing system without detergents.

- Water quench systems without the use of polymers or oils make this a “green” option when compared to the more traditional Oil Tempered process.

Tech Specs

- Designed to process high carbon spring steels such as SAE9254 and equivalents, typical finished properties are tensile strengths of 2000MP with ductility of more than 40% ROA.

| Minimum Diameter | 7mm (others by request) |

| Maximum Diameter | 18mm continuous/ 22mm coil to coil |

| Production Rate Options | 2T or 3T with continuous production |