SeamScan™

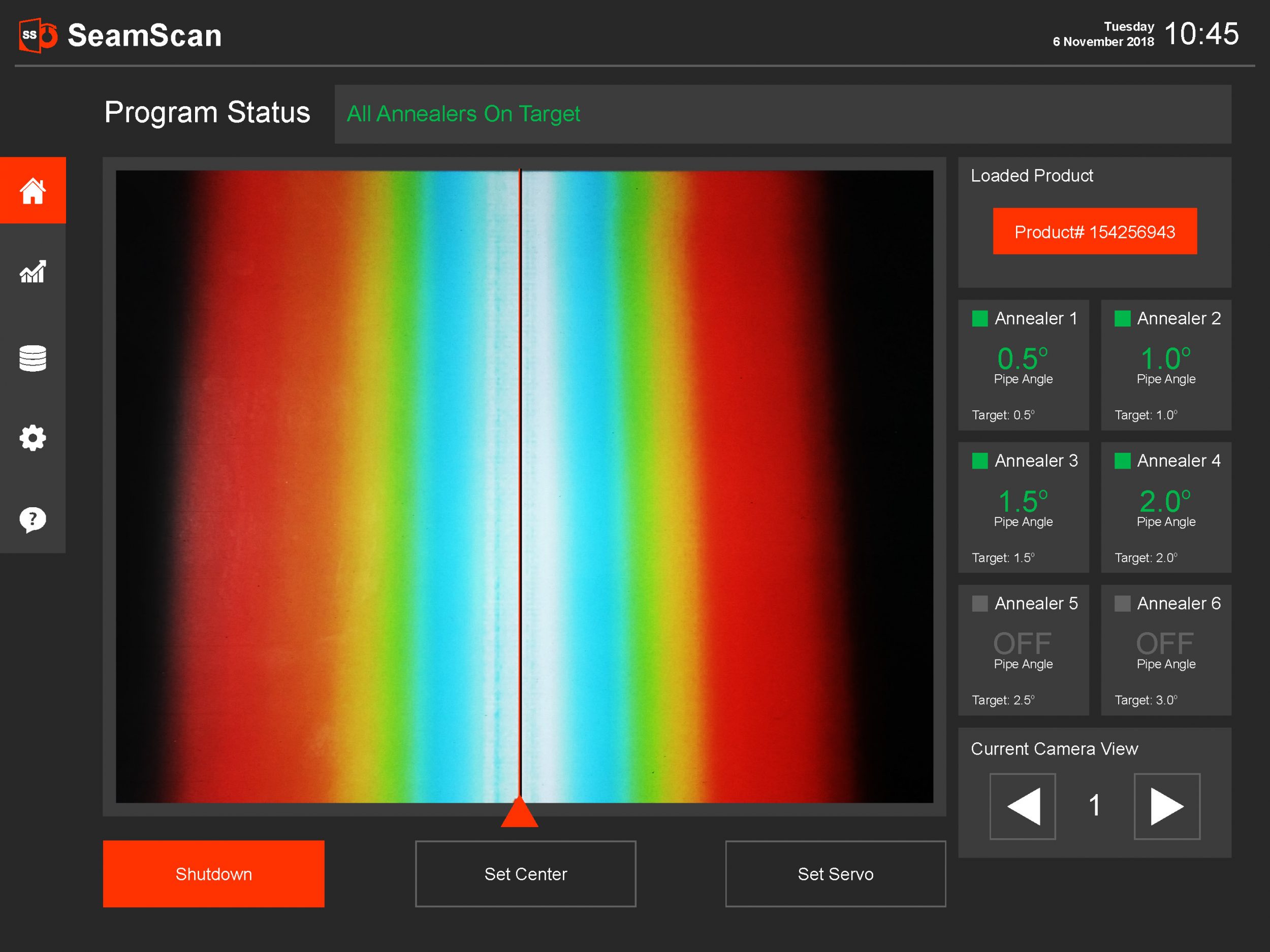

SeamScan™ is an advanced thermal seam tracking package designed for Thermatool Seam Annealers. The tracking equipment utilizes state-of-the-art thermal cameras and image processing technology to detect the HF welded seam. SeamScan™ automatically positions each annealer inductor over the weld seam to ensure accurate heating. This control platform consists of a thermal camera, image processor CPU, and a touch screen which communicates via ethernet to each seam annealer’s PLC (requires SmartAnneal™ option).

Features

- The software algorithm calculates the correct position for each annealer inductor along the hot seam, tracking the seam twist in the mill.

- Annealer controls allow the system to automatically rotate the annealer inductor orbitally around the circumference of the pipe (6” pipe and larger).

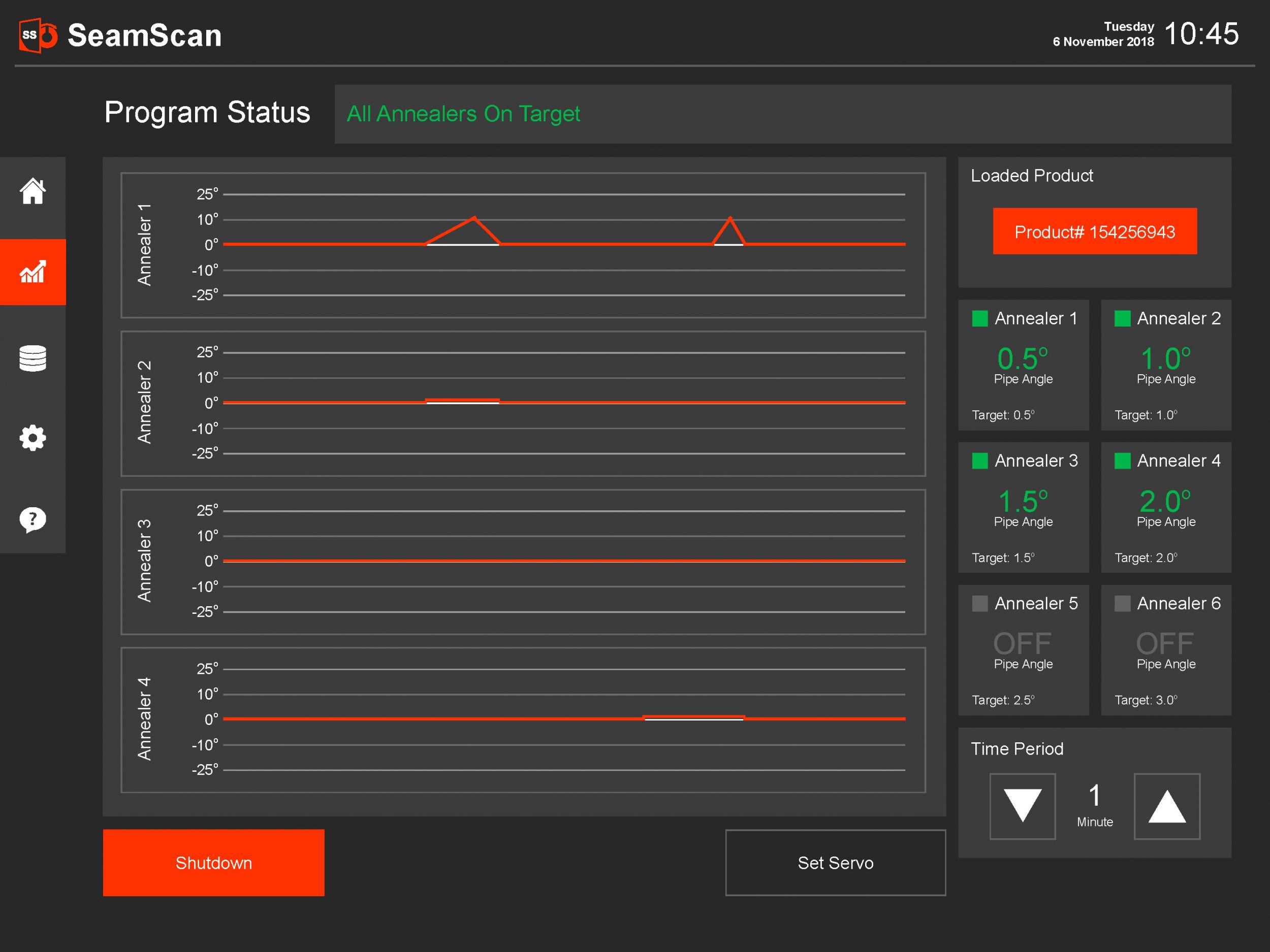

- Displays pipe angle and angle of each inductor.

- The inductor position and seam angle are graphed in real-time (±15o seam twist maximum).

- The product recipe can be saved for each pipe OD and air gap.

- Recipe settings can be data-logged to a text file available for post-process review (export via USB or ethernet).

- Eliminates unreliable line painting and visual camera painted line tracking system.