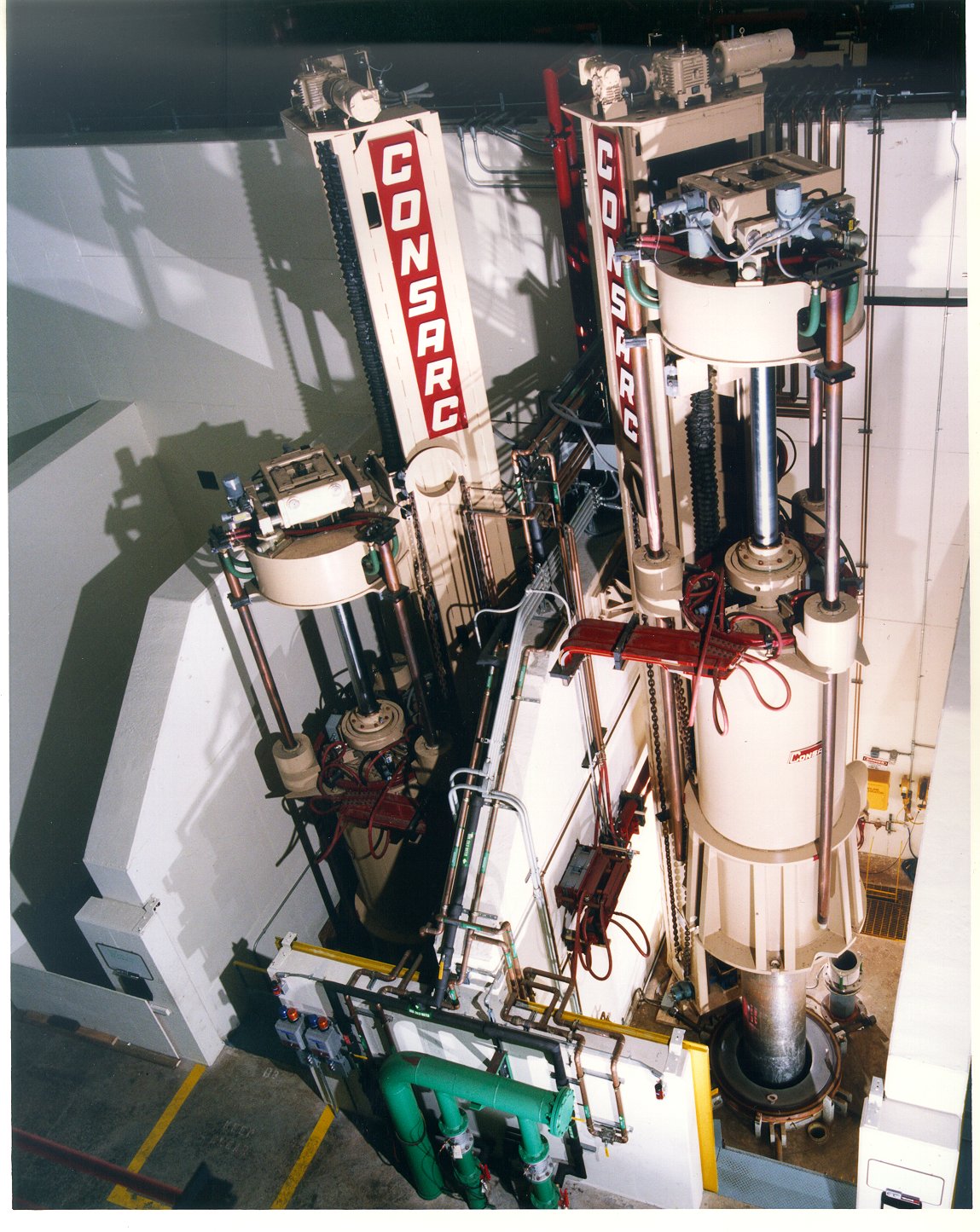

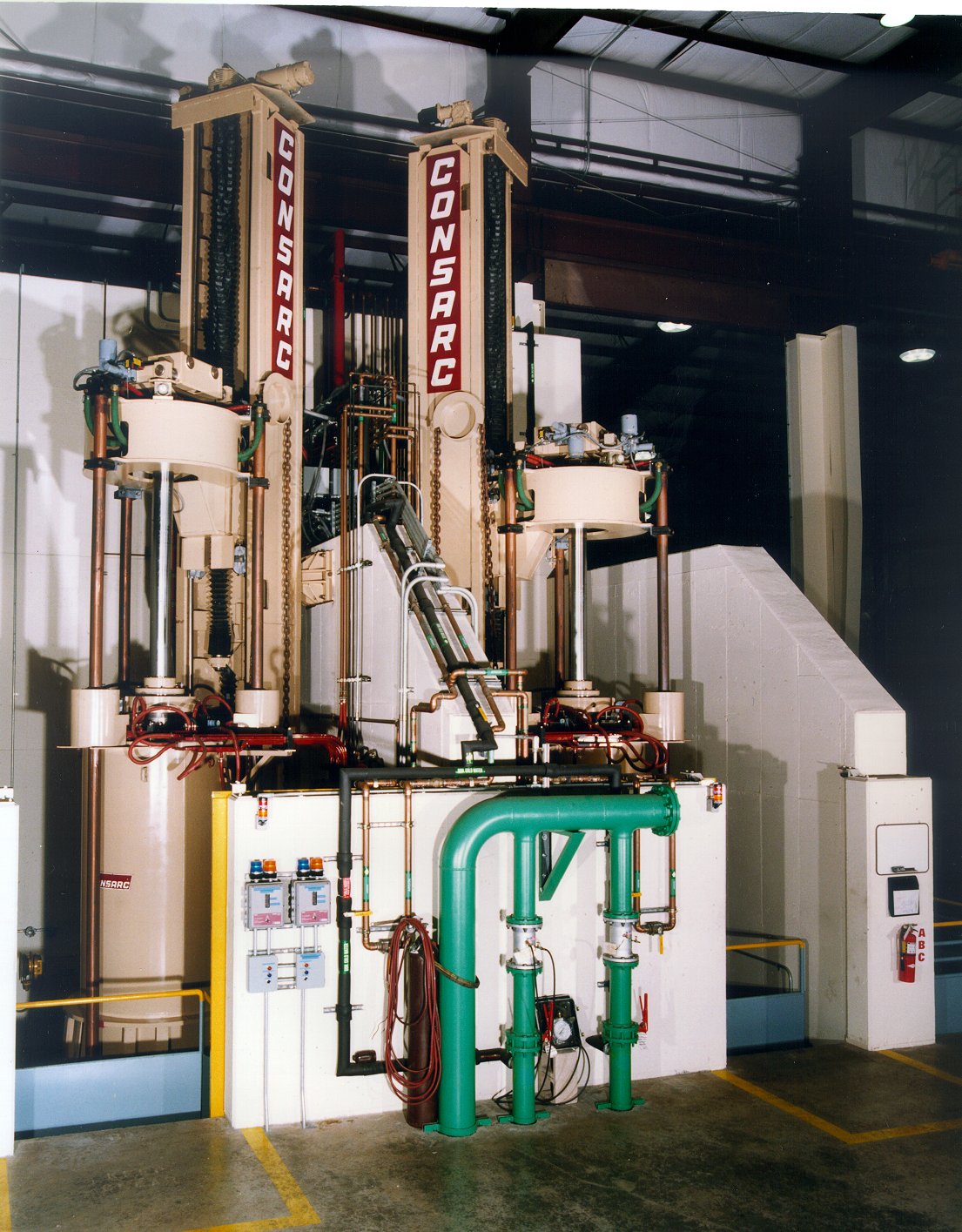

Reactive VAR Furnaces (RVAR)

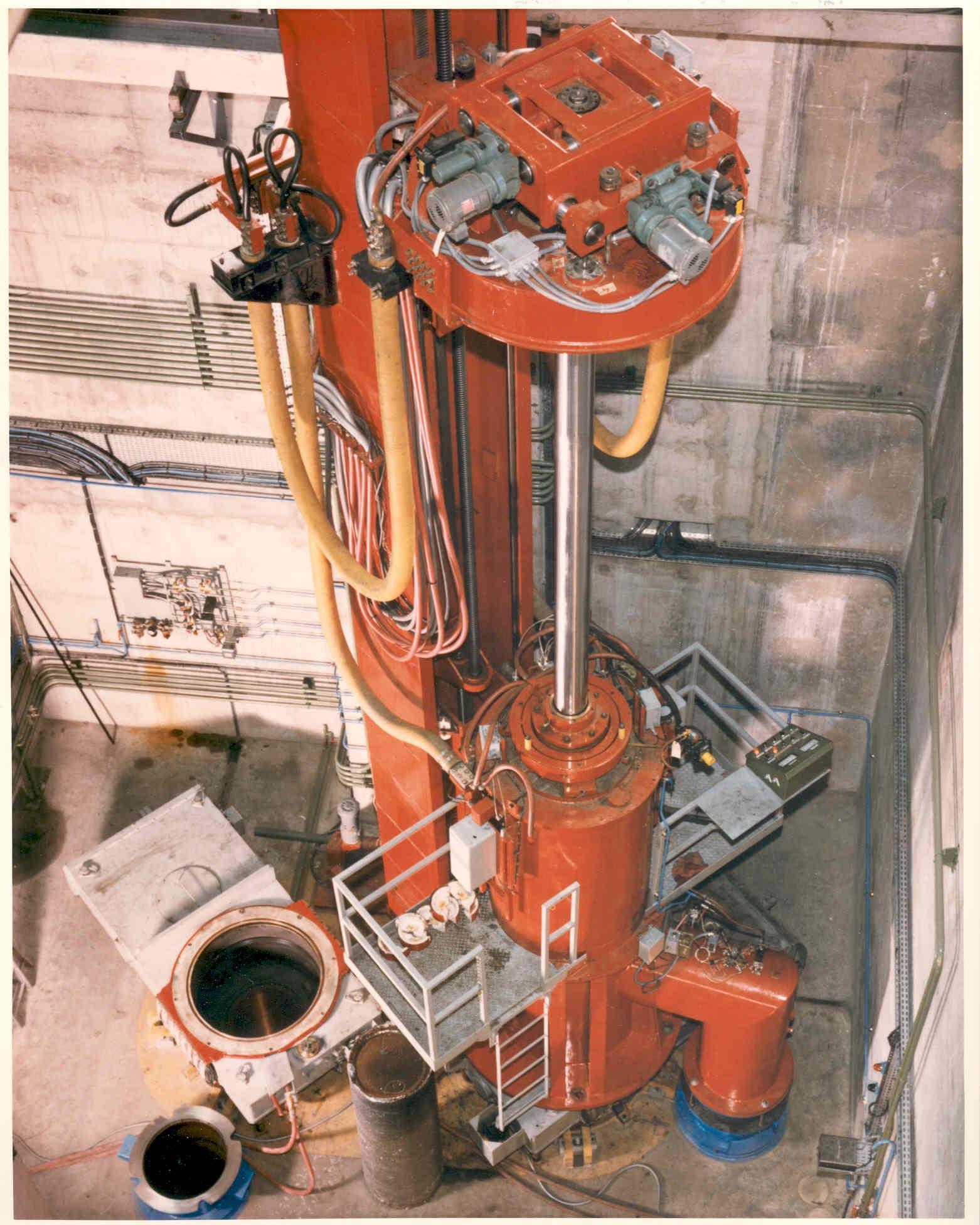

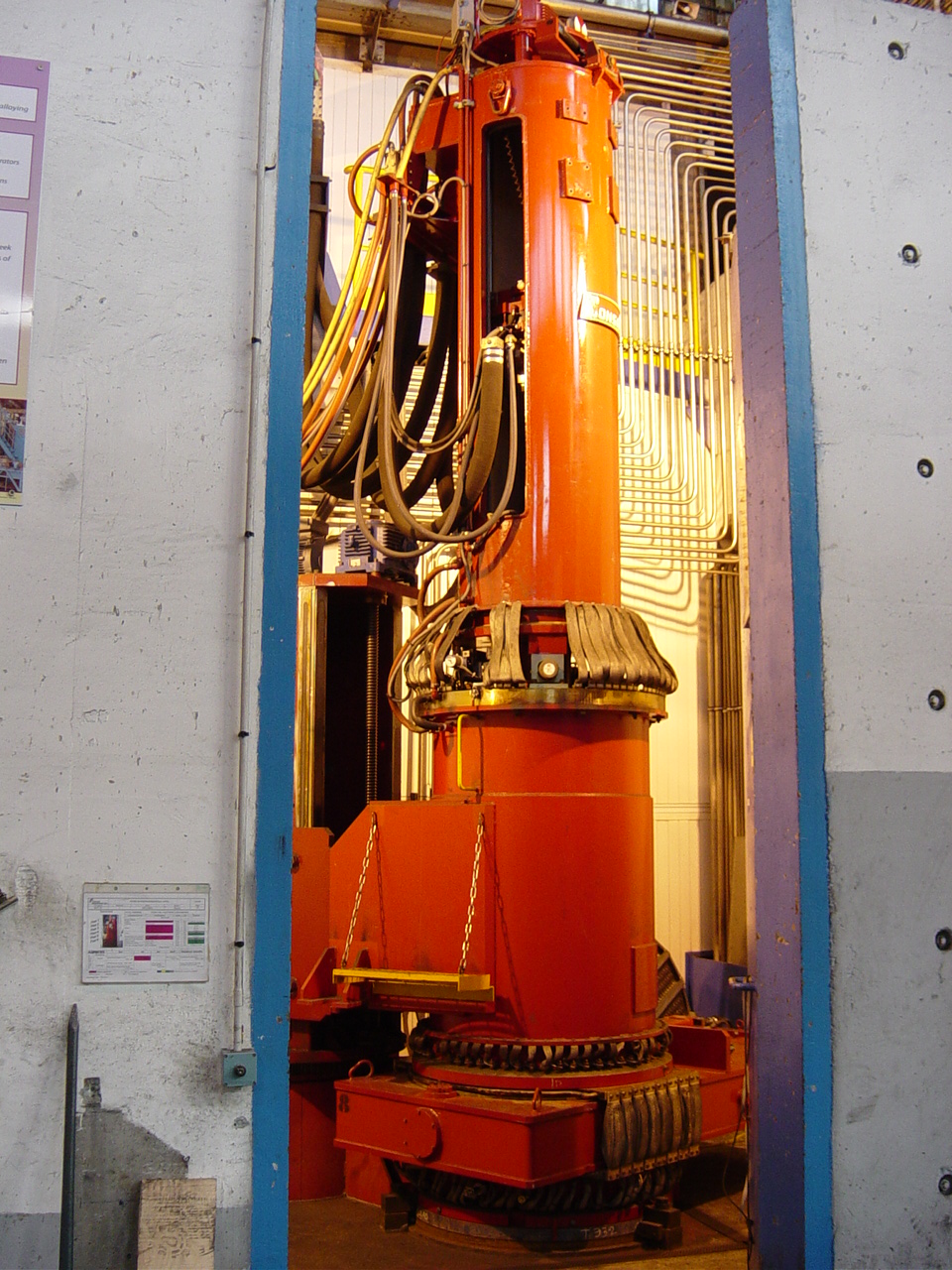

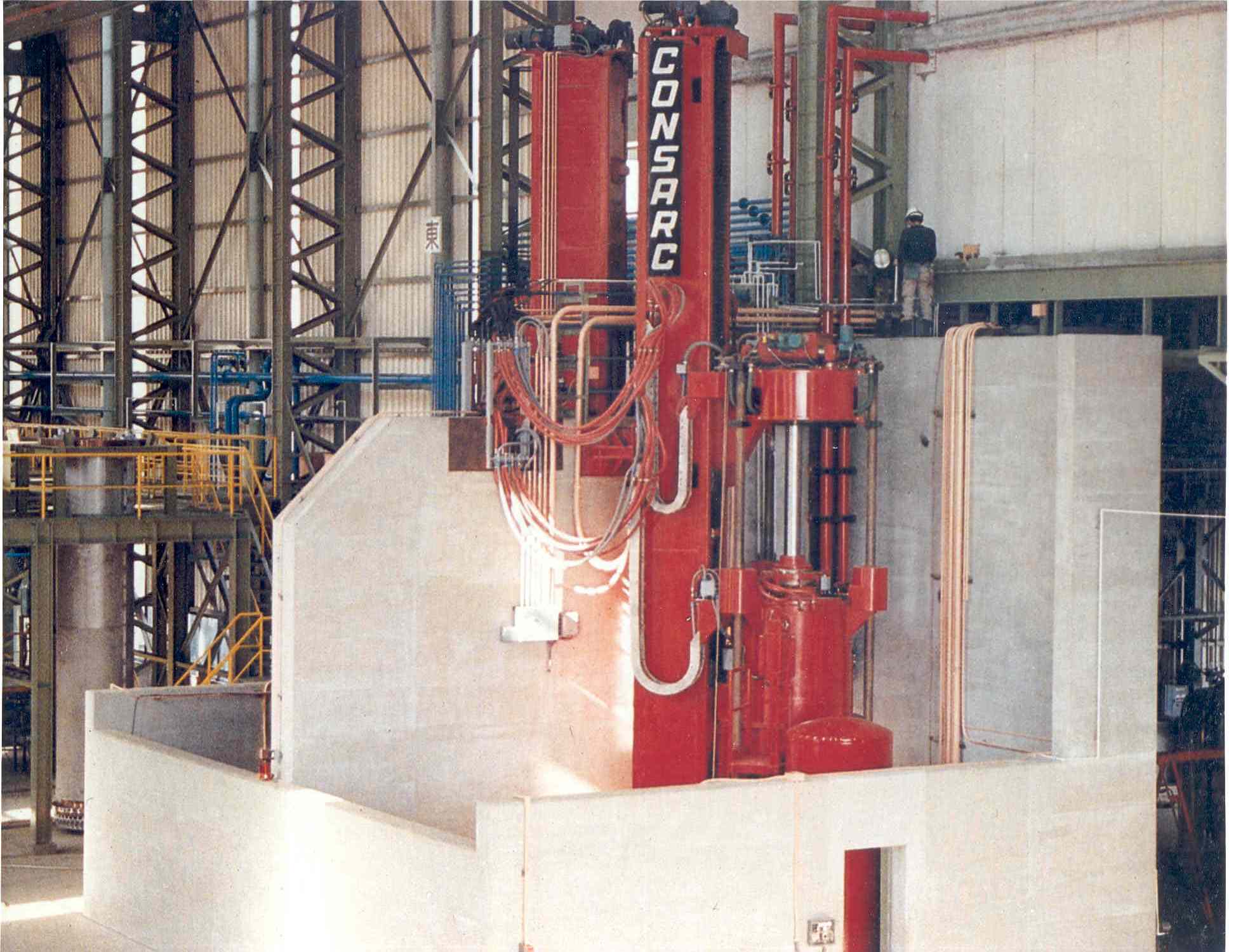

RVAR Furnaces for the production of reactive materials, such as titanium, being produced from low packing density material such as sponge compacts or bulk welded materials. The low packing density electrodes requires that the furnace has extensive ram travel and volume within the crucible and head to melt the entire electrode into an ingot. The Consarc RVAR furnace, with its column design allows the ram drive and head lift to collapse on one another minimizing the overall furnace height while maximizing the head and ram travel available.

Consarc RVAR furnaces are available in a wide array of combinations of furnace heads, melt stations, and power supplies to match production levels with an economical quantity of materials.

Features

- Coaxial current furnace design to reduce magnetic stirring within the solidifying ingot

- X-Y electrode positioning to center the electrode and improve ingot quality

- Rotary Piston or Dry Screw Pump vacuum systems available

- Closed loop economizer cooling system or recirculating crucible water circuit

- Fully automated controls from start-up through completion of hot top

- Full suite of safety features including argon gas backfill, reasealing overpressure relief valves and PLC safety logic

- Single servo motor ram drive

- Precision melt rate control using load cells

- No hydraulics – all motions are electromechanical or pneumatic

- Stirring coils integrated into water jacket for process control

Tech Specs

| 36″ (900 mm) RVAR | 42″ (1050 mm) RVAR | 48″ (1200 mm RVAR) | ||

| Maximum Ingot Weight | 20,000 lbs (9,000 kg) | 42,000 lbs (19,000 kg) | 55,000 lbs (25,000 kg) | |

| Maximum Crucible Diameter | 36″ (900 mm) | 42″ (1,050 mm) | 48″ (1,200 mm) | |

| Crucible Flange Diameter | 49.5″ (1,257 mm) | 56″ ( mm) | 64.5″ ( mm) | |

| Recommended Power Supply | 35,000 Amps | 44,000 Amps | 44,000 Amps | |

| Maximum Ram Travel | 150″ (1,778 mm) | 200″ (5,080 mm) | 200″ (5,080 mm) | |

| Maximum Head Lift | 120″ (3,048 mm) | 155″ (3,937 mm) | 155″ (3,937 mm) |

Accessories

- Allen Bradley or Siemens PLC processors

- Vacuum Stub Welders

- Water Cooled Lock Valves