Mini-Melt Furnaces

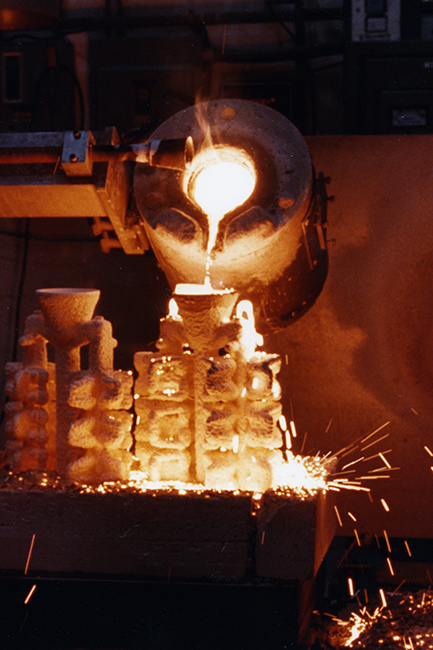

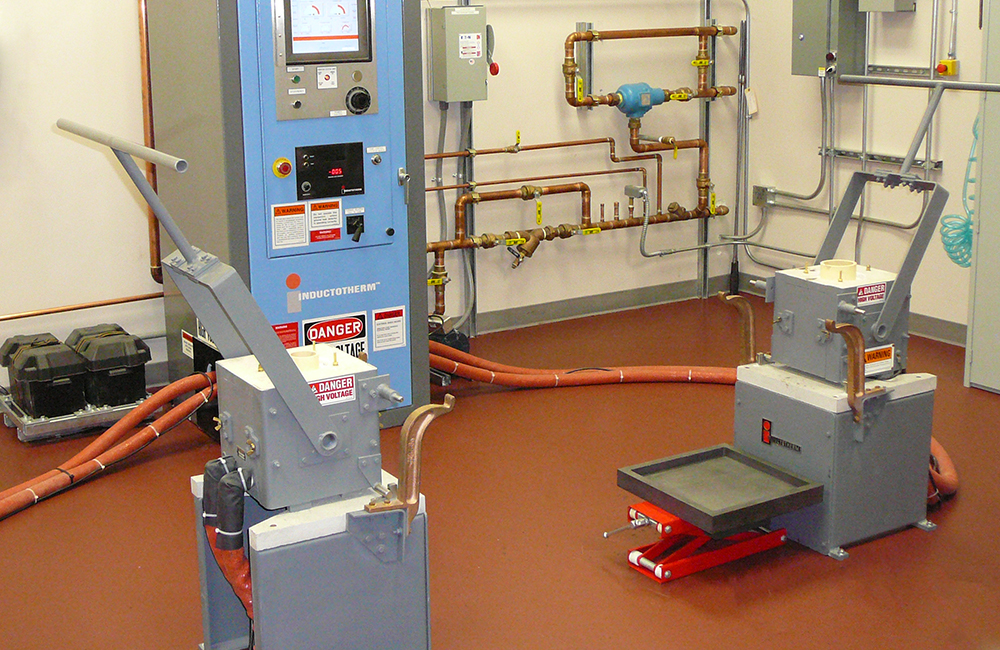

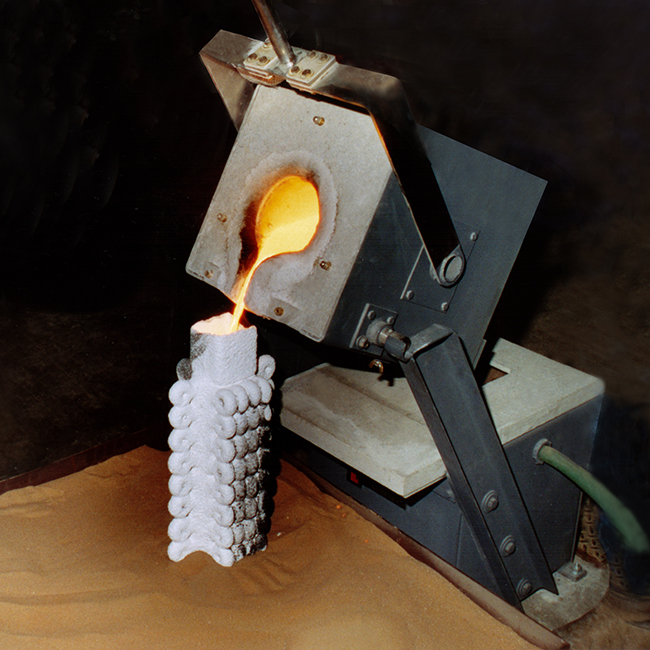

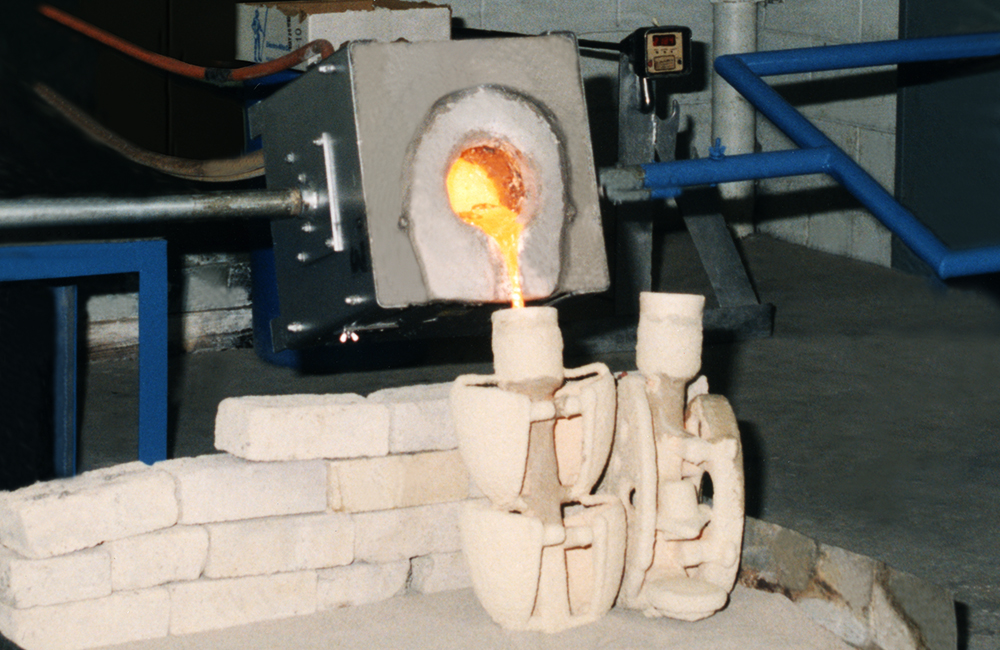

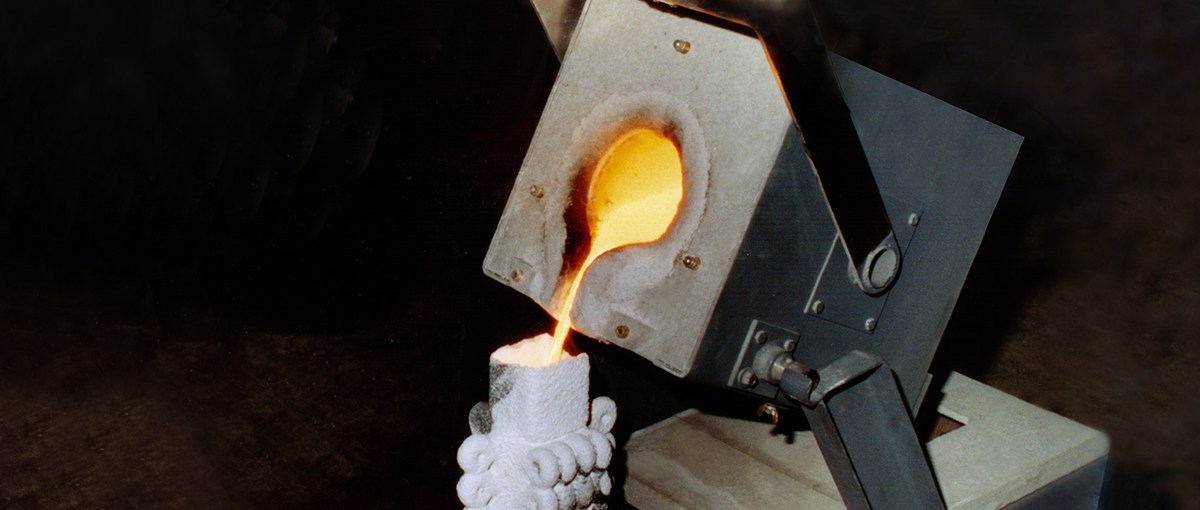

Mini-Melt® Furnaces are small capacity induction furnaces designed to meet the demanding requirements of investment casters and others.

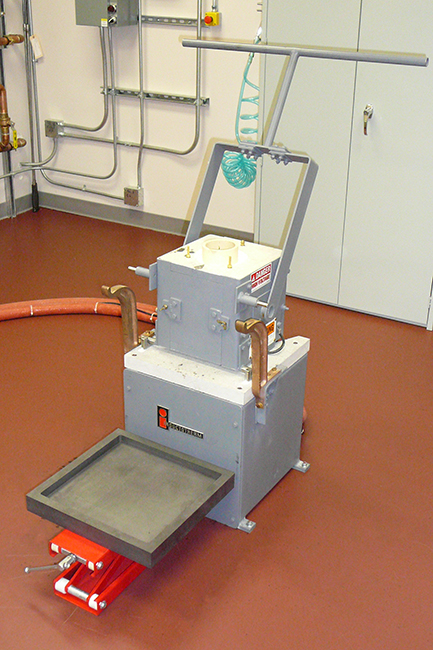

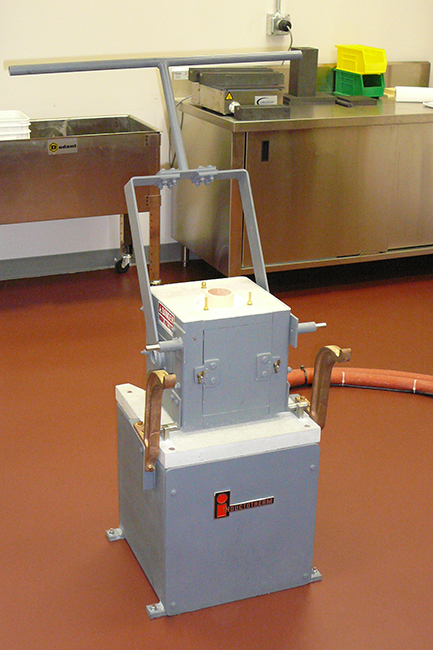

Mini-Melt® Furnaces are table-mounted and hand-operated. They are built with materials that provide exceptional structural strength and reduced weight, key factors in furnaces designed to be moved and poured by hand. Featuring rugged ceramic tops and bottoms with durable aluminum alloy sides, they are 20 to 25 percent lighter than comparable ceramic-shell furnaces and 40 to 45 percent lighter than aluminum-frame furnaces.

This reduction in furnace weight is a particularly important consideration in hand pouring operations. Their removable front and back inspection and access panels make Mini-Melt® Furnaces easier to maintain and cost less to repair than shell furnaces and aluminum frame furnaces. These furnaces have a strong, durable construction for long furnace life. They also operate at frequencies from 3,000 to 10,000 hertz with maximum power utilization. Mini-Melt® Furnaces are ideal for use in prototype casting, small run casting, precious metal refining and casting, laboratory operations and wherever relatively small amounts of molten metal are needed.

Tech Specs

| Capacities | Standard Features | Optional Features | Factory Tested |

|---|---|---|---|

| 2.5 to 25 Kilograms [5 to 50 Pounds] | Two Direct-Pouring Styles: Two-Man Shank and Trunnion Tilt | Direct Lead Connection | Critical Components |

| Contact Inductotherm for Custom Solutions | Removable Front and Back Inspection and Access Panels | Power Clamp Table | |

| Lifting and Titling Shanks | |||

| Cast Ceramic Tops and Bottoms |