Inductoforge® Induction Billet Heating Systems for Forging

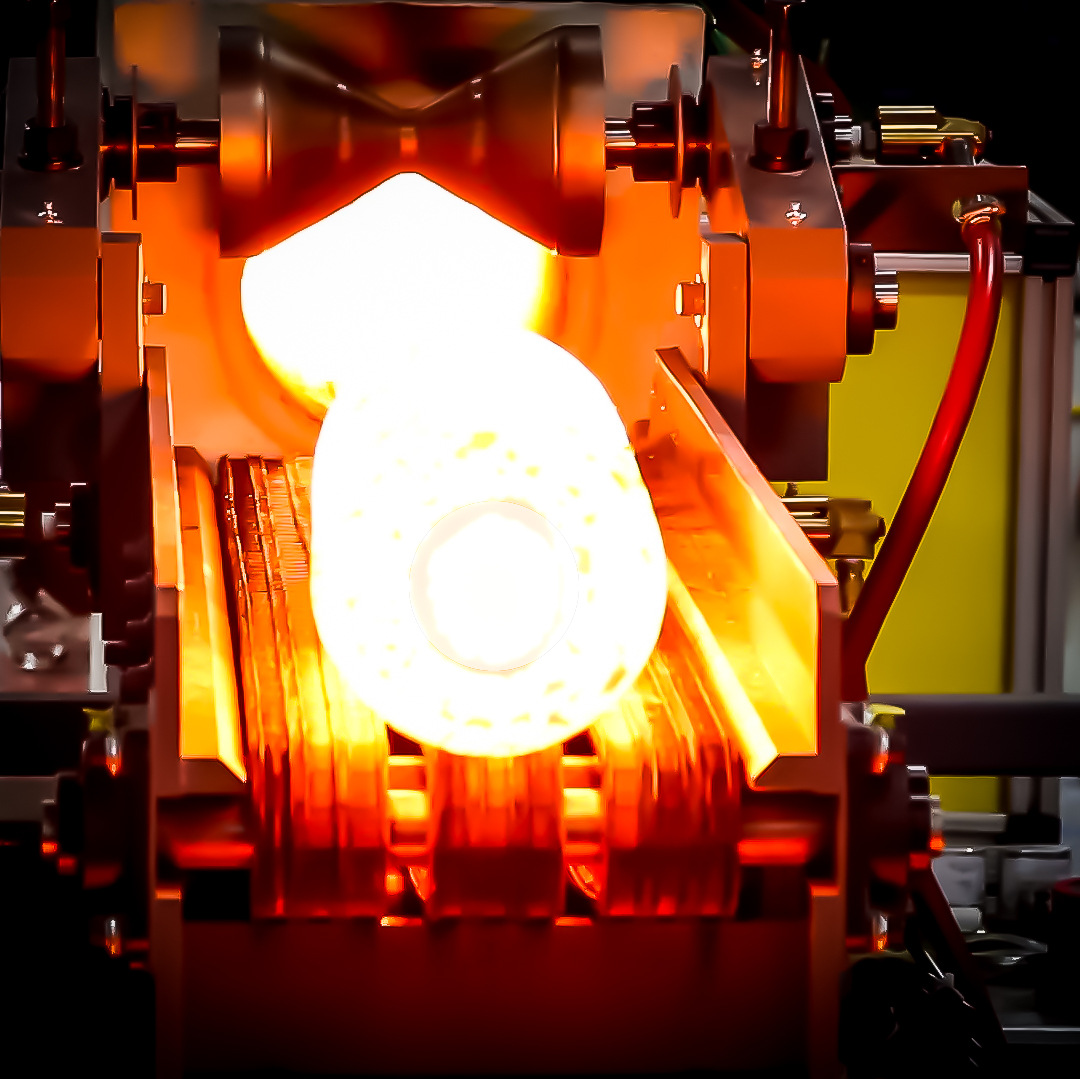

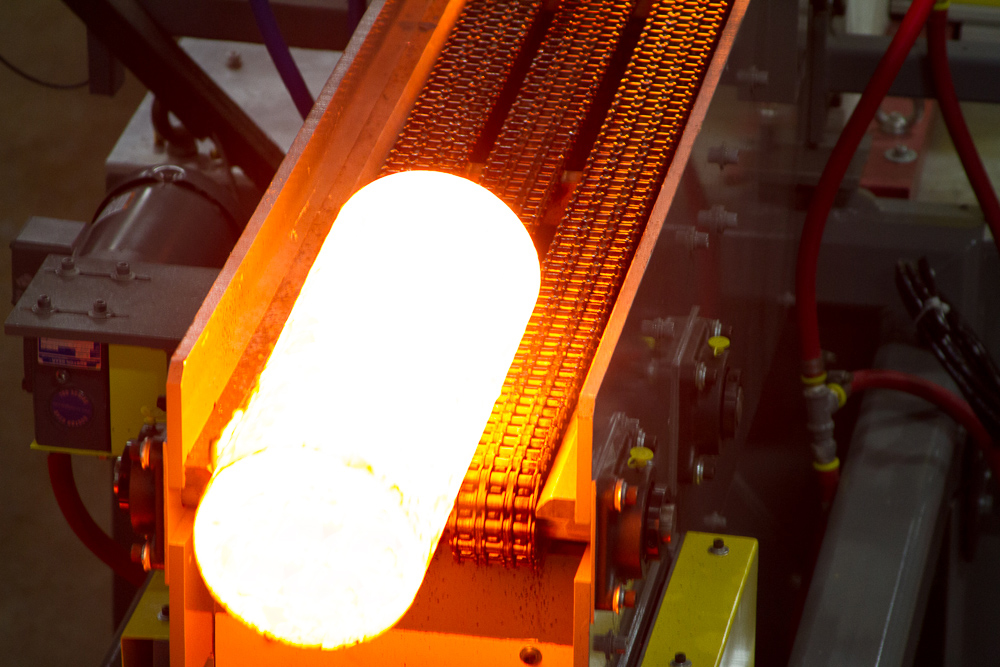

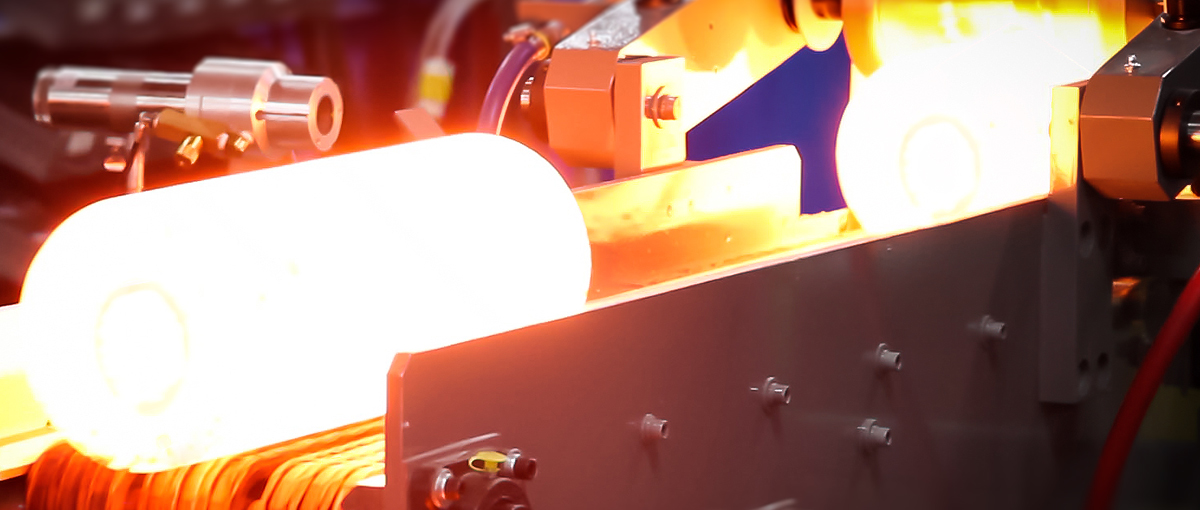

Induction billet heating for forging allows modern-day forge shops to quickly heat up material ensuring uniform temperature and unmatched efficiency.

The Inductoforge® Induction Billet Heating system is a revolutionary product for the forging industry giving the modern day forge shops the ability to heat billets to the proper forging temperature while optimizing efficiency. The flexible modular design allows the induction heating to match a customer’s forging application while providing the flexibility for future expansion. The powerful combination of advanced engineering, product innovation and over 55 years of experience in induction heating had made the Inductoforge® billet heating system the world leader in induction heating for forging.

The key feature to the Inductoforge® Billet Heating System is that each system is equipped with individual power modules that allow for individual power control on an induction heating coil. The ability to individually control power to each induction heating coil allows forging customers the flexibility to heat a range of billet diameters at different desired production rates while maintaining acceptable surface to core temperature uniformity. To assist the forge shop, all Inductoforge® Billet Heating Systems are supplied with our proprietary iHAZ Temperature Profile Modeling Software that is a predictive numerical simulation technology that accurately forecasts temperature uniformity throughout the cross-section of the billet. By utilizing the iHAZ Temperature Profile Modeling Software, ideal system recipes can be set up to delivery properly heated billets, maintain acceptable surface to core temperature uniformity, and optimize overall system efficiency.

Utilizing state of the art software and advanced modular power control has made the Inductoforge® Billet Heating System truly the most advanced induction heating system in the forging industry.

Induction Billet Heating System Features

The Inductoforge® Modular Induction Billet Heating System offers flexibility and efficiency with its individually controlled (500Hz – 6000Hz) power modules. The Inductoforge® billet heating systems utilize our proprietary iHaz™ Temperature Profile Modeling Software giving the user the tools to generate an ideal system recipe and precisely heated billet.

The iHaz™ software package is a predictive numerical simulation technology that accurately forecasts the temperature throughout the cross-section of the billet, from the surface to the core. The heating system’s modular design makes it possible to employ a standby function that keeps the billet at temperature, ready to start forging immediately following minor line disruptions.

Features & Benefits:

Eliminates heating recipe guesswork

Optimal system efficiency

Unmatched temperature uniformity

The industry’s most advanced heating technology

Modular design permits standby functionality (hot parts ready immediately following minor line disruptions)

Material Handling Systems:

| Automatic Feed | Magazine hopper, step feeder, bowl feeder, feeder/loader, conveyor feeder, v-flight conveyor |

| Billet transport | Conveyors, robot grip chutes, billet weighing system |

| Extraction | Inductoforge™ billet extractor, pinch roll extraction |

| Drive Systems | Pusher, pinch roll, tractor drive |

| Accept/Reject | Single, dual color pyrometers |

Tech Specs

| Model | Dimensions | Weight | ||

| 1 Module (500) | 198″ (5092 mm) L, 75″ (1905 mm) H, 48″ (1219 mm) W | 3000 (1660 kg) | ||

| 2 Module (900) | 257″ (6527 mm) L, 75″(1905 mm) H, 48″ (1219 mm) W | 5000 (2268 kg) | ||

| 3 Module (1250) | 335″ (8509 mm) L, 85″ (2159 mm) H, 48″ (1219 mm) W | 7000 (3175 kg) | ||

| 3 Module (1500) | 354″ (8991 mm) L, 85″ (2159 mm) H, 56″ (1422 mm) W | 7100 (3175 kg) | ||

| 4 Module (2000) | 431″ (10947mm) L, 85″ (2159 mm) H, 56″ (1422 mm) W | 9000 (4082 kg) | ||

| 5 Module (2500) | 598″(15,189 mm) L, 85″ (2159 mm) H, 56″ (1422 mm) W | 11000 (4989 kg) | ||

| 6 Module (3000) | 689″ (17,500 mm) L, 85″ (2159 mm) H, 56″ (1422 mm) W | 130000 (5896 kg) | ||

| Capabilities | 3300 lbs. (1496.8 kg) – 22000 lbs. (9979 kg)/hr | |||

| Power Output | 300kW to 5.4MW | |||

| Output Frequency | 500Hz, 1000Hz, 3000Hz, 6000hZ, 1000/3000Hz, 3000Hz/6000Hz | |||

Accessories

• Pinch roll and tractor chain infeed systems

• Hot billet extraction equipment

• Automatic billet feeding systems

• iHAZ™ Advanced temperature control

• Optional billet clean out system

• Coil shuttle table

• Accept/reject system

• Robot interface kit