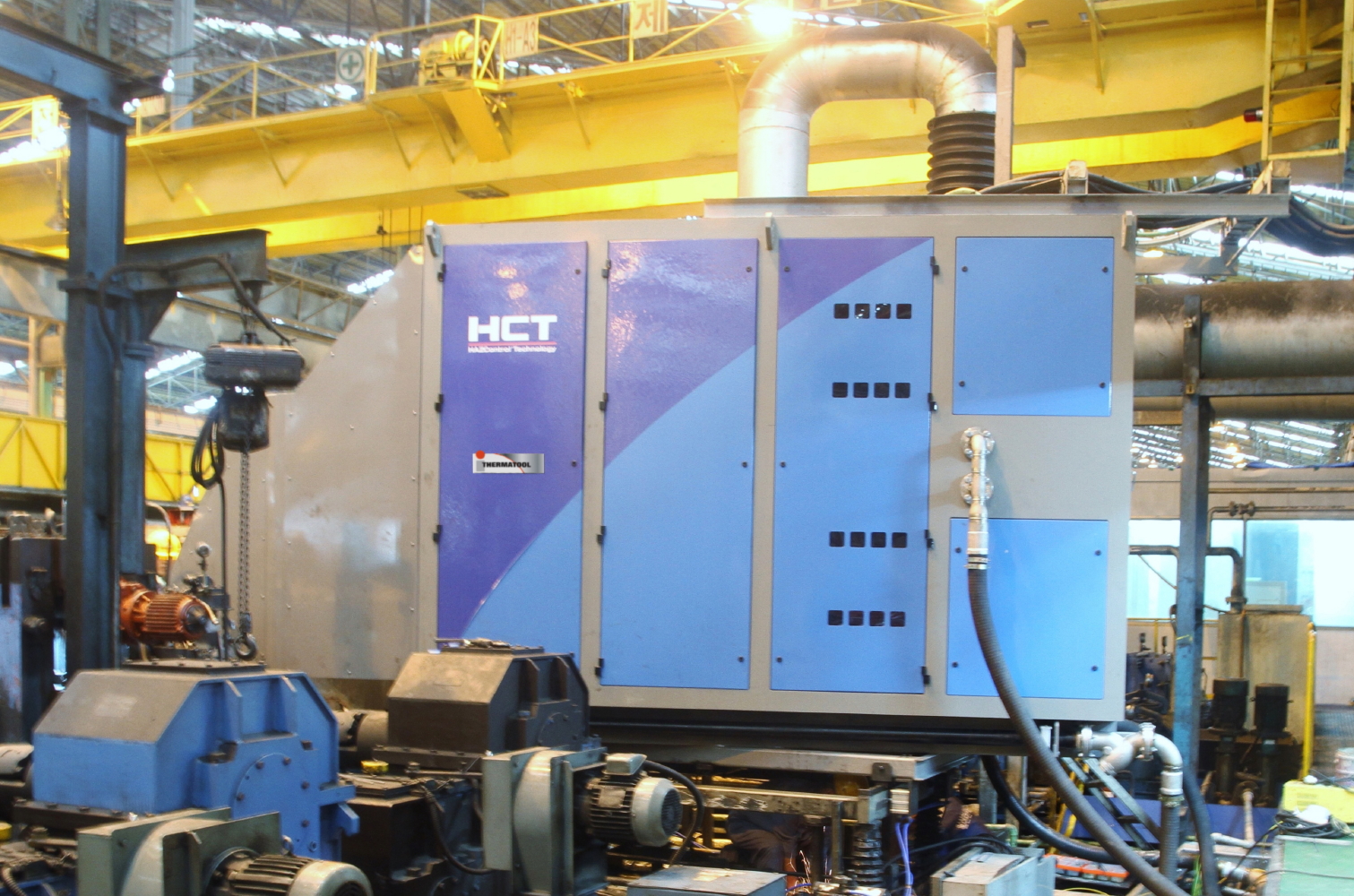

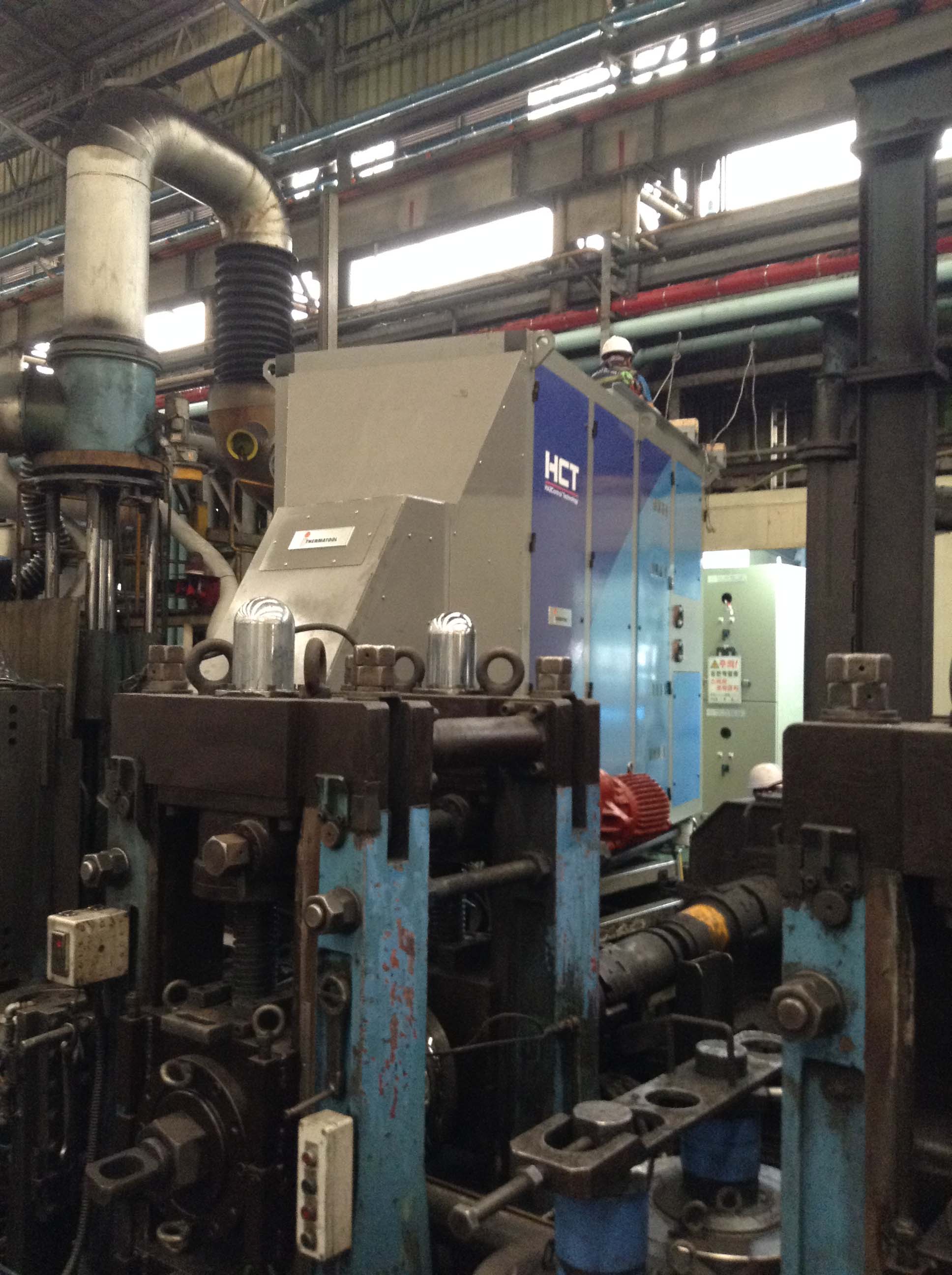

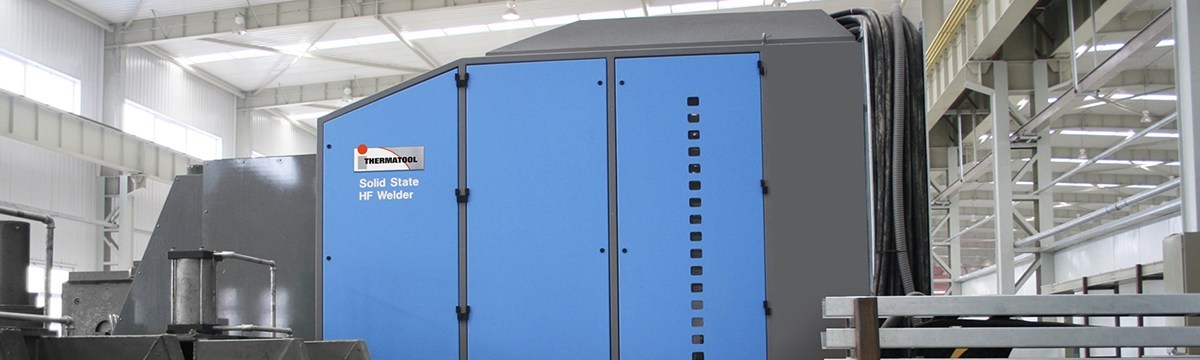

High Power High Frequency Welders

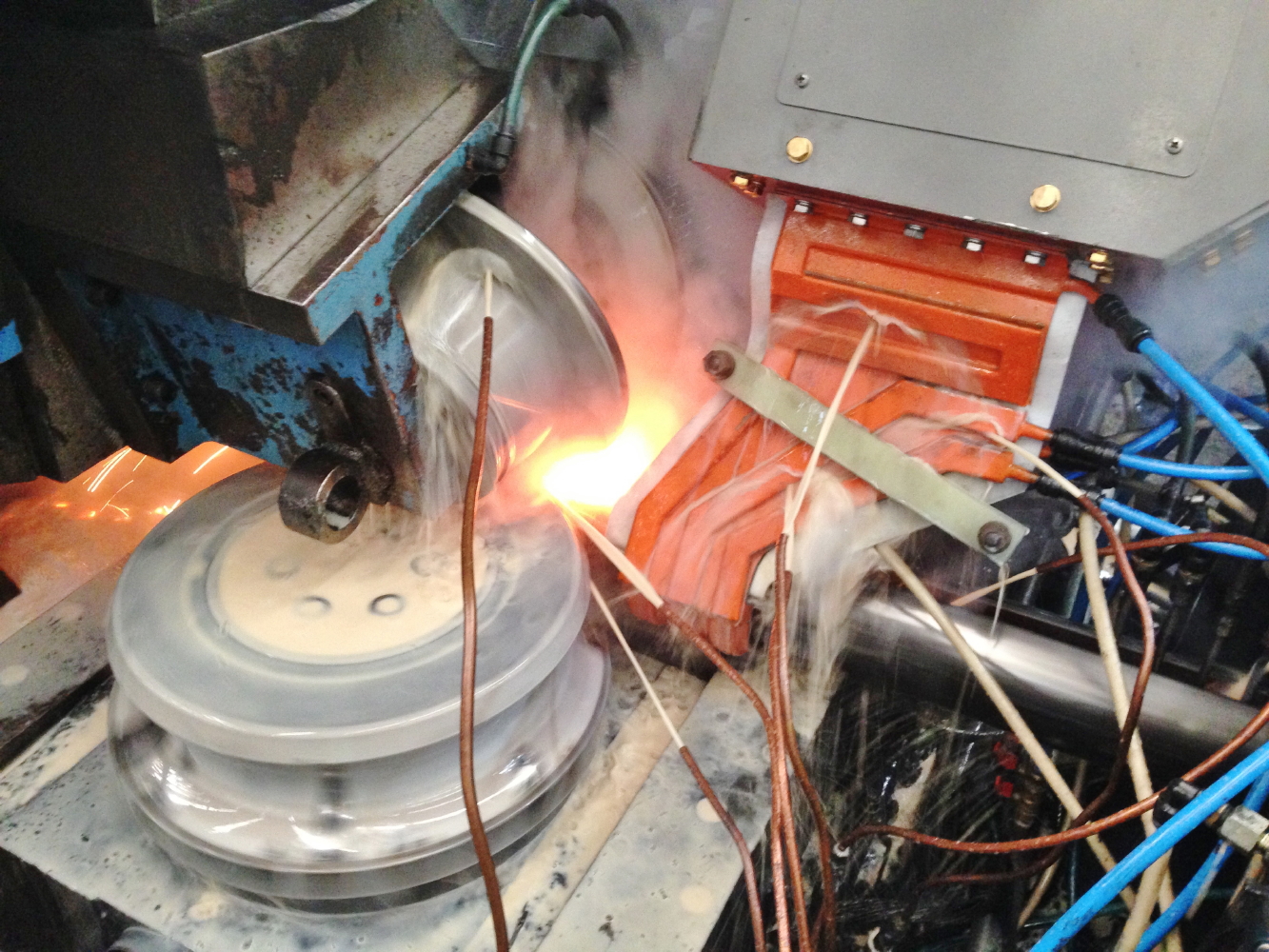

With power ranging from 1000 – 2000 kW, Thermatool High Power High Frequency Welders are capable of welding from 150 – 400 kHz with fixed or variable frequency. These welders perform in the most demanding applications. Thermatool High Power HF Welders are available with the innovative 221 coil or the patented QuadContact™ weld tooling for the highest quality HF Weld available on the market. Thermatool welders over 1000 kW are installed in applications up to 610 mm (24 inch) diameter and up to 25 mm wall (1 inch) at speeds up to 40 mpm (130 fpm).

As the only global induction heating and welding manufacturer specializing in tube and pipe welders, Thermatool provides the widest range of HF Welders available.

All of our welders are based on the High Frequency or “HF” welding process that we developed almost 60 years ago and have led the way ever since. With its Current-Fed Inverter (CFI) design, our welding equipment range gives you the capability to successfully weld almost any metal you want – efficiently and economically.

We supply equipment needed to weld carbon and stainless steel, brass, copper, and aluminum, as well as exotic alloys, such as boron steel and HSLA, AHSS, and Trip Steels.

Features

- A high efficiency rating of 85% to meet the ever increasing worldwide electrical energy standards.

- Patented full range Thermatool AutoMatch™ ensures full power output over wide range of product sizes.

- Quad contacts and variable geometry induction coil for big pipe coil and coil mills.

- Available with HAZControl™ Welder Technology variable frequency option.

- HAZControl™ Welder Technology Variable Frequency Bands available: 250 kHz – 300 kHz, 300 kHz – 350 kHz, 350 kHz to 400 kHz.

- Power set-point maintained within 0.5%.

- Frequency set-point maintained within 1.0%

- Available with dual induction/contact output.

- Excellent low weld power output stability and regulation for welding at mill jog speeds (as low as 1% power).

- Power factor over 0.95. With power factor correction.

- DC Ripple less than 0.5%.

- Low harmonic distortion rectifier.

- Equipped with Speed Power Control giving the operator the tools that are needed to start, stop and jog the mill while welding – this keeps scrap to a minimum by reducing open seam.

- Primary isolated power supply DC rectifier.

- Power supply is completely sealed with high quality gaskets, thus eliminating contamination.

- Doors are fitted with lift-off hinges for easy access.

Tech Specs

| Power Range | Up to 2000 kW |

| Output Frequency | 200-400 kHz + 1% stabilized frequency per load requirements |

| Diameter Range | Unlimited |

| Induction Coils | Standard |

| HF Contact Welding | Yes |

| Dual Induction Contact | Yes |

| Weld Tables | Single, 2, 3, VeeAxisTM |

| AutoMatch™ | Yes |

| PLC | Yes |

| Speed Power Control | Yes |

| Tachometer | Yes |

| Efficiency | > 85% |

| Power Factor | 0.92 |

| Ripple | ~1 |

| WeldScan | Yes |

| ThermaView | Yes |

| ThermaSure | Yes |

Consumables

Induction Coils

Thermatool offers a comprehensive range of induction coils, designed specifically for use with Thermatool solid-state HF induction welders. Manufactured from high conductivity copper, quality inspected and coated for long life, there are numerous types and sizes available to satisfy every application. Many of these models are available for immediate delivery from stock.

Whether you are producing carbon steel, stainless steel, copper, brass, aluminum or galvanized tubing, Thermatool has the induction coil to meet your specific needs. Our comprehensive range of induction coils fully supports the entire range of Thermatool welders with power ratings from 50 kW to 2 MW and operating frequencies ranging from 150 kHz to 800 kHz and variable frequency.

For special coil requirements, Thermatool engineers are pleased to review the possibility of a custom coil design/build.

Impeders

Thermatool offers an extensive range of impeders to satisfy a very diverse range of tube and pipe welding applications. Whether your mill produces small diameter/thin wall tubing or large diameter/heavy wall API line pipe, Thermatool supplies a complete selection for you. The proper choice of impeder, correctly installed, will play a major part in achieving maximum welding efficiency. It should also be noted that as the performance of all ferromagnetic materials is a function of temperature, it is critically important that the ferrite core is kept as cool as possible during the tube welding process. Ideally, the temperature of the coolant flowing through an impeder should not exceed 25°C. Thermatool also supplies booster pumps for these demanding applications.

Ferrites

Modern tube mills that operate at higher line speeds have created demand for impeders that deliver superior performance. Such enhanced performance can only be achieved by using the very best ferrites available. A growing number of tube and pipe producers worldwide choose Thermatool ferrites in order to optimize the performance of their mills. Thermatool offers four different types of ferrites which can be cut to length, if required. Contact us today to learn more!