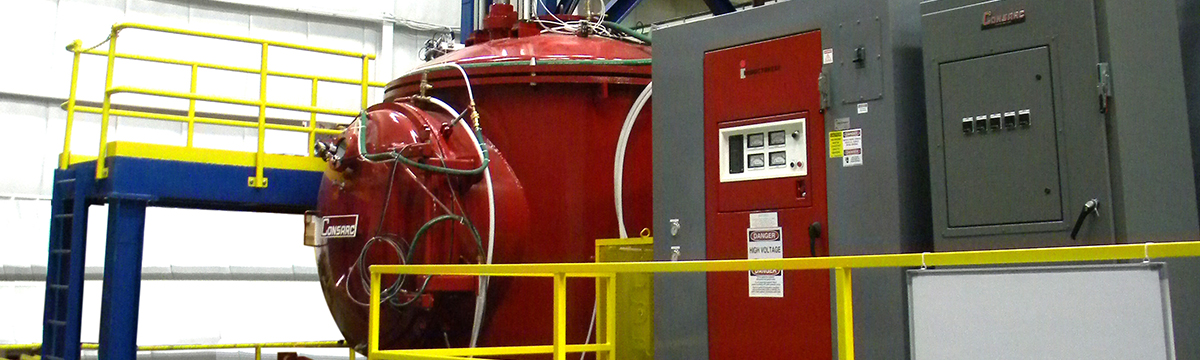

Electromagnetic Cold Crucible

Electromagnetic Cold Crucible (EMCC) is an innovative process utilizing a segmented water-cooled copper crucible for refractory-free induction melting, while under vacuum or controlled atmosphere. Melting in a water-cooled copper crucible eliminates the possibility of contamination from the fused silica solar crucible.

The copper crucible is made up of water-cooled segments or “fingers.” The magnetic field produced by the coil, in effect, passes through the crucible to induce heat into the silicon. The magnetic field also intensely stirs the liquid pool and promotes a very homogeneous melt.

Features

Non-Consumable/Non-Contamination Crucible Design:

Consarc’s water cooled segmented copper crucible is designed for multiple heats compared to the one time use of a fused silica solar crucible in a traditional DS furnace. Another major advantage of the EMCC furnace is that the silicon melt is levitated off the water-cooled walls of the crucible, thus avoiding contamination of the molten silicon.

Reduced Capital Cost:

The EMCC furnace will displace a number of traditional DS furnaces; savings will be achieved with a reduction in factory space and high equipment consumption.

Reduced Operational Cost:

Less man power requirements, Shorter cycle times and Crucible is reusable.

Tech Specs

Consarc’s EMCC Furnaces are custom engineered to fit your needs.