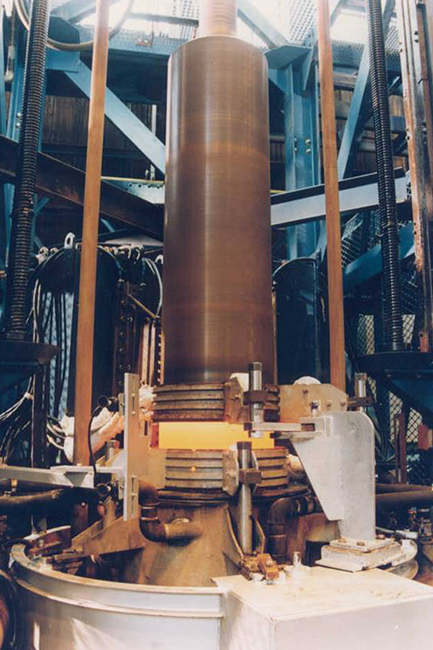

Mill Roll Hardening Systems

Mill Roll Hardening Systems are becoming increasingly popular with the expanding development of cold mills which subject the rolls to high stresses. For the surface heating of steel parts, induction heating is considered to be the application best suited for this. Induction heating has many applications and is especially effective in hardening rolling mill rolls.

Features

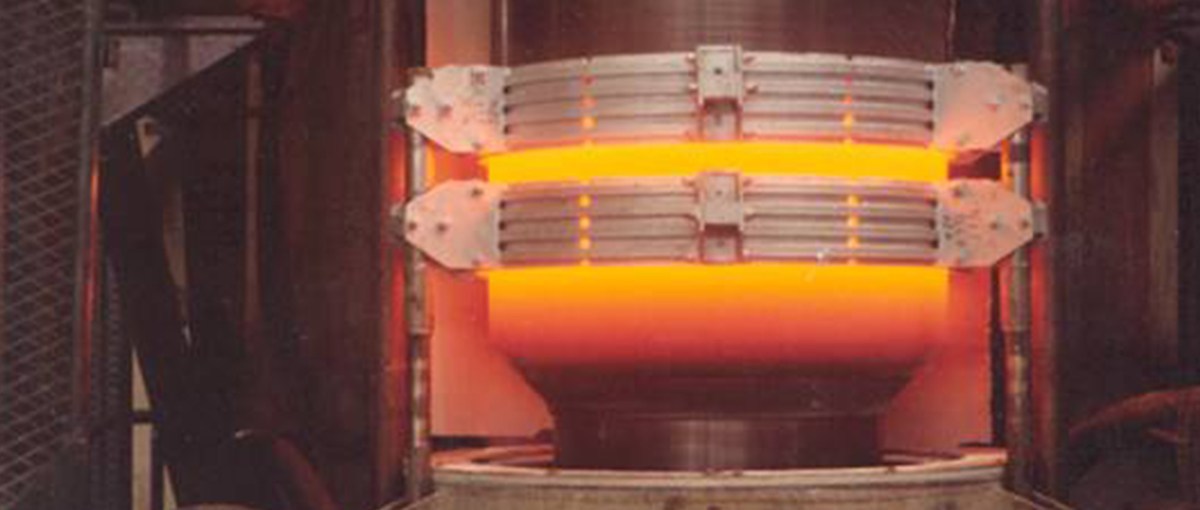

Mill Roll Hardening Systems are becoming increasingly popular with the expanding development of cold mills which subject the rolls to high stresses. These systems are used to obtain rolls with high strength and resistance to surface wear. Induction heating has greatly contributed to improvements in hardening depth, with subsequent improvement in distribution of residual stresses. These systems offer:

- Increased roll life

- Reduced number of retreatments before rolls wear out

- Various operating frequencies to optimize case depth

- Optional split coil designs to accommodate the hardening of longer rolls

Tech Specs

Contact Inductotherm for Custom Solutions